| « 2020-06-06 | Tinkering | 2019-12-17 » |

Tinkering: 2019-12-29: Dowelling Jig for Face-To-Edge Connections

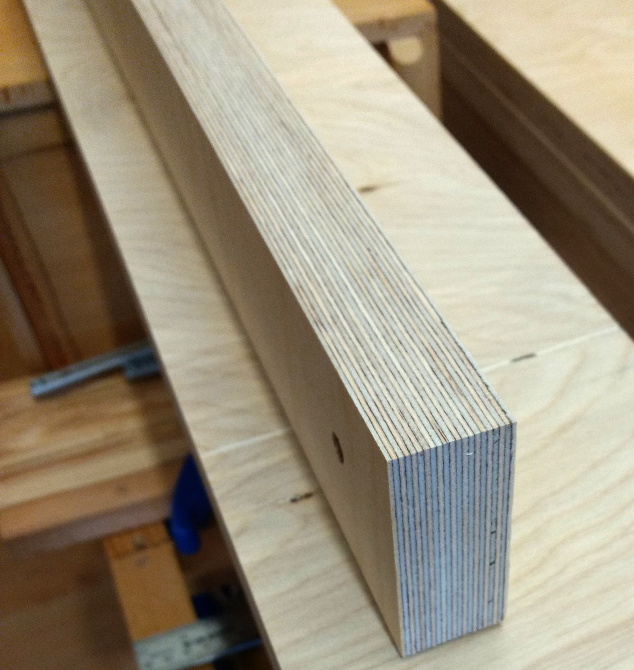

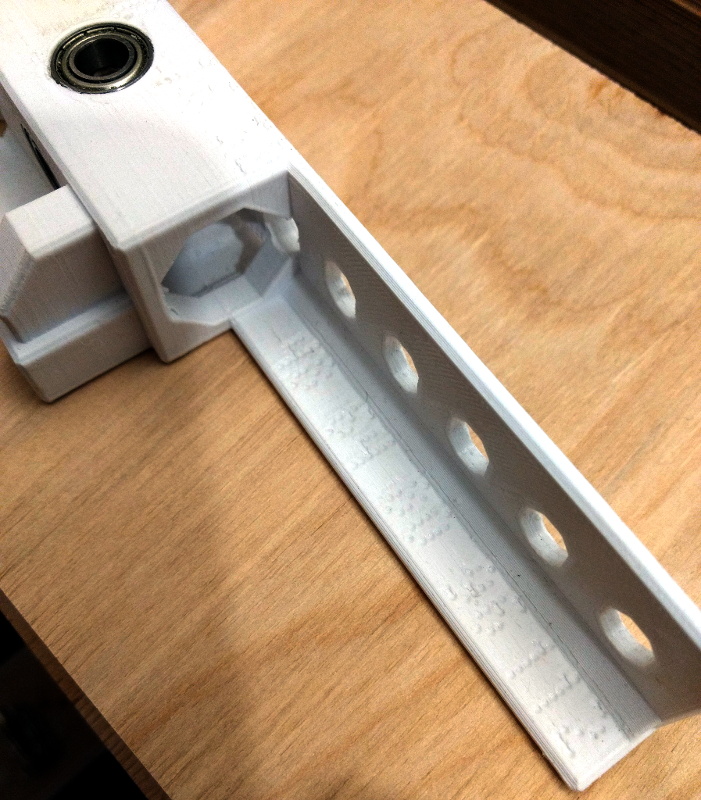

This is my dowelling jig for gluing two parts of wood together in such a way that the edge of one part connects to the face of the other.

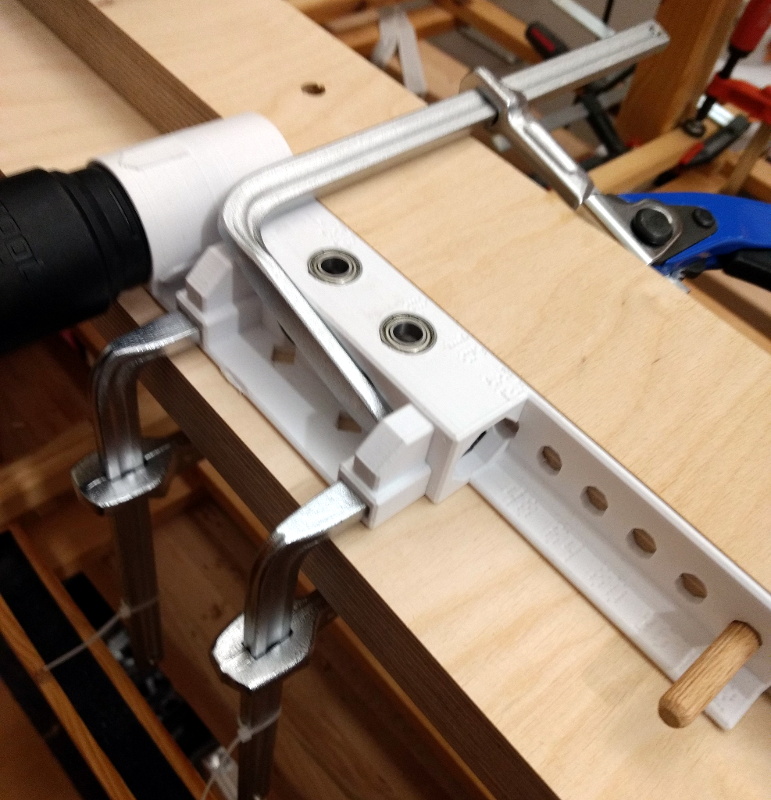

The jig positions dowels exactly opposite in the two parts to be joined, with minimal error. This is achieved by clamping the two parts together, the one with the face facing up and the one with the edge turned by 90°.

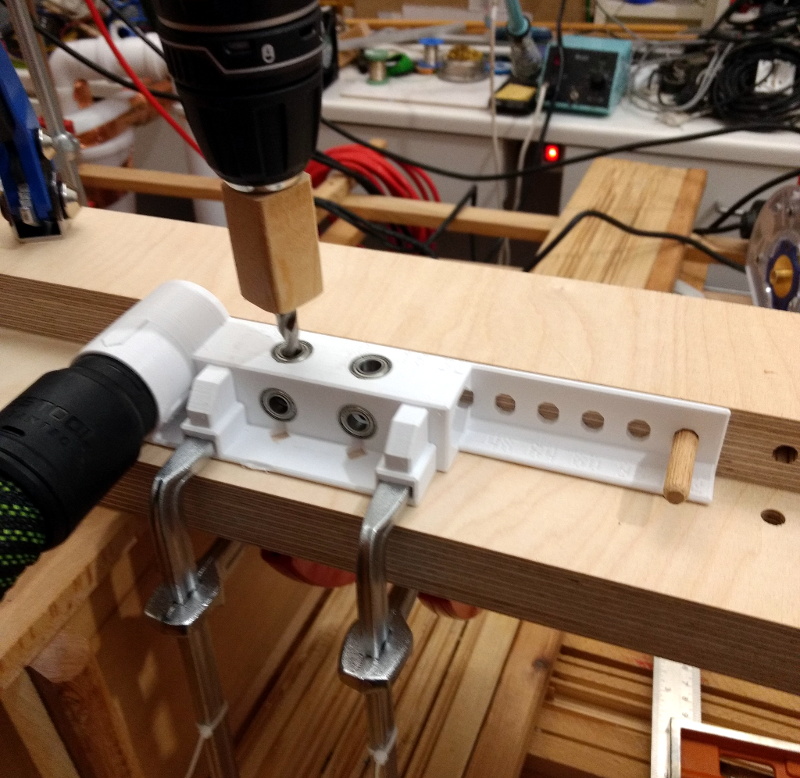

The dowel holes for each pair of dowels can be drilled without moving any part or repositioning the jig.

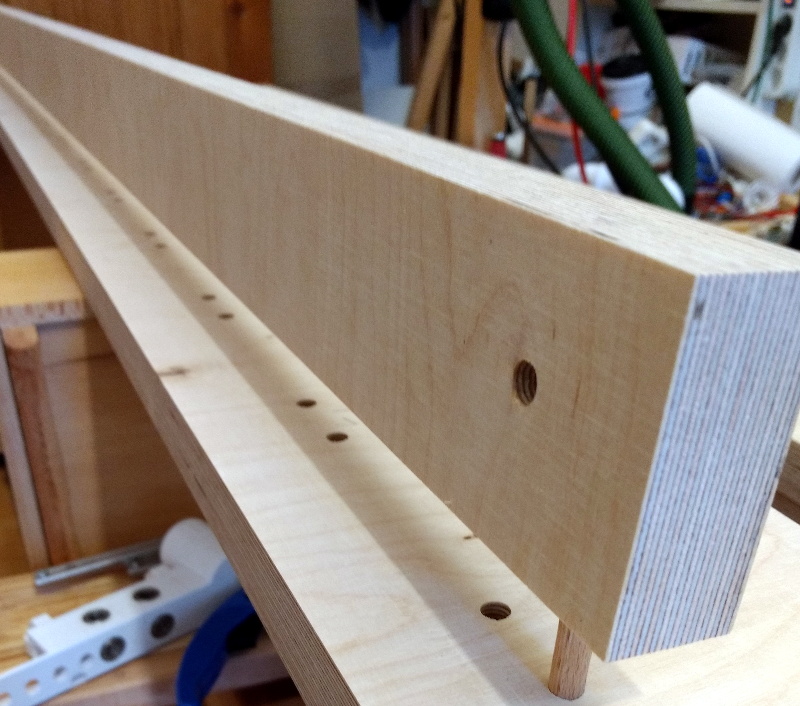

The jig can be positioned based on marks, as it has a notch at both drill positions.

Alternatively, to make a series of holes, the jig can be positioned relative to an existing hole in steps of 16mm by using a dowel. The positioning holes on the jig are labelled in mm.

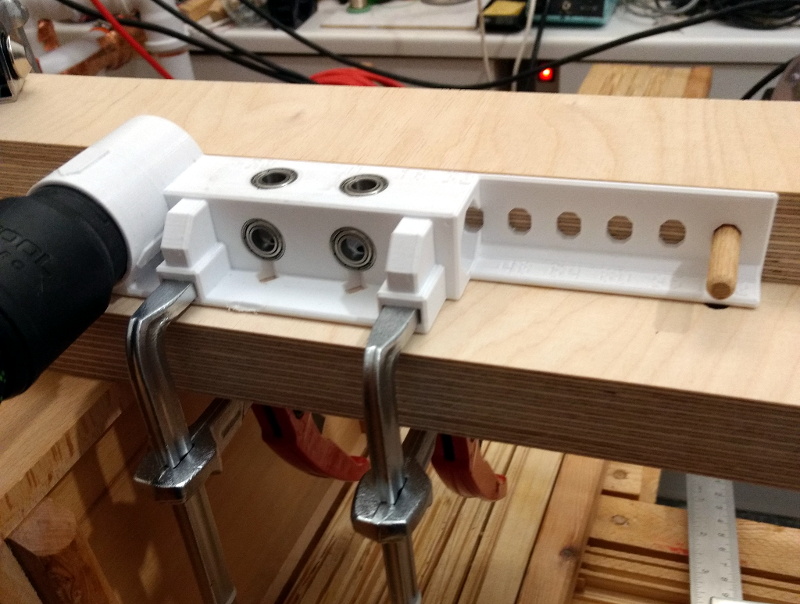

There are channels for standard T-slot clamps so that the jig can be clamped down if it is used close enough to the edge. To position the jig properly, another clamp can be used temporarily to pull it firmly into place, if possible.

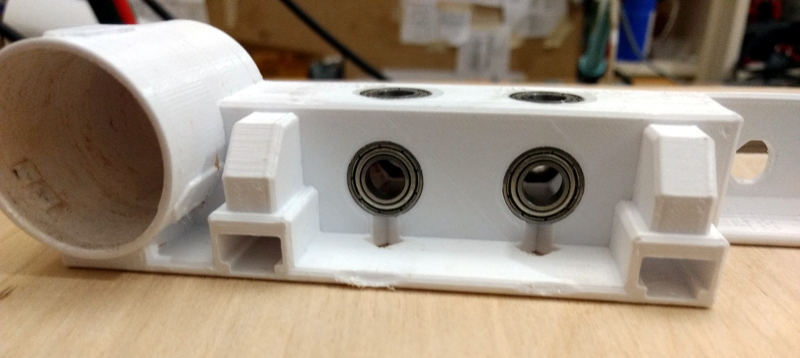

The jig has superb dust collection thanks to a shopvac socket for a Festool shopvac hose. Usually, there is literally no wood chip escaping while drilling or when the drill is pulled back. The jig acts a bit like a whistle, however...

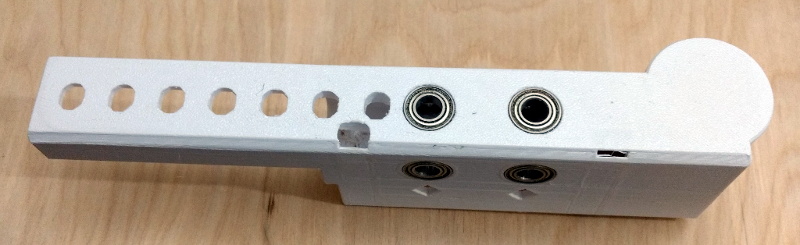

The following is a back side view of the jig. You can see that the wall behind the clamp channel is a bit weak and I pushed one out the first time I tried it with a clamp. PET is quite brittle, maybe other thermoplastics work better.

This jig can be used to drill pairs of 8mm holes with a distance of 32mm in one go. 32mm is the standard distance used in cabinets and also used by more professional (power) tools.

The jig is made for boards that are 30mm thick, i.e., the holes are 15mm from the bottom and 15mm from the back of the jig. Other sizes can be joined, too, but this requires shimming the turned part before clamping it to the other part. E.g., a 18mm board can be dowel connected to the face of another board by shimming it up by 6mm (which is (30mm - 18mm)/2).

For guiding the drill, ball bearings are used. The jig is designed for standard 688 ball bearings, which are 8x16x5 (all sizes in mm).

You could use 625 (5x16x5) ball bearings for 5mm holes, 696A (6x16x5) ball bearings for 6mm holes, MR1016 (10x16x4) ball bearings for 10mm holes. However, the dowel series functionality would not work properly anymore, because the positioning holes are also 8mm.

Since I had trouble logging into Thingiverse, I switched to PrusaPrinters for sharing this build:

Download files from PrusaPrinters project page